Forklift Signs-- Inexpensive Safety Solutions for Industrial Workplaces

Forklift Signs-- Inexpensive Safety Solutions for Industrial Workplaces

Blog Article

Forklift Security Indications: Important Tips for Optimal Positioning and Exposure

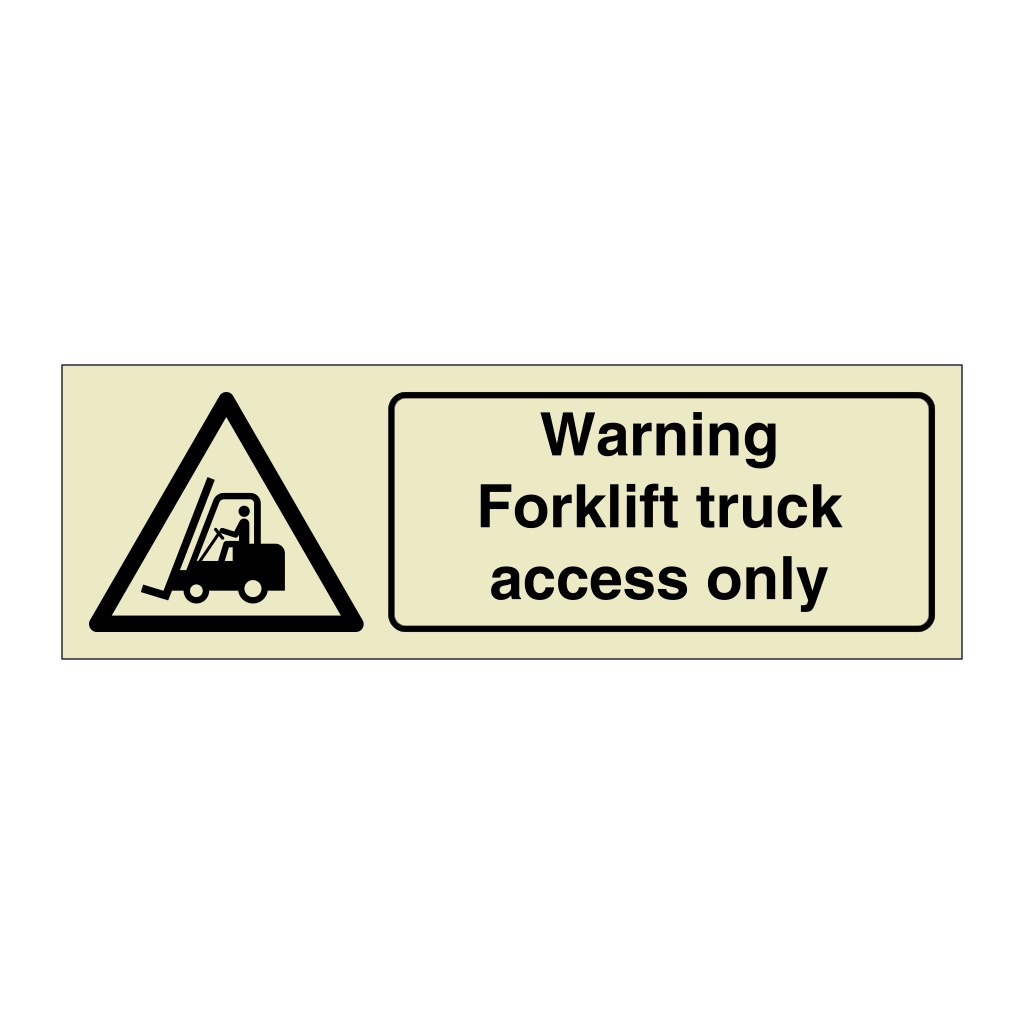

Ensuring the ideal positioning and presence of forklift safety and security indicators is essential in preserving a protected industrial atmosphere. Positioning these indications at calculated places such as entrance and leave points of filling docks, crucial center crossways, and high-traffic storage space locations can dramatically reduce mishap risks.

Trick Locations for Safety And Security Signs

Correct positioning of forklift security indications is important for maintaining a safe functioning environment. In addition, putting signs near high-traffic storage space locations and blind areas can further enhance presence and recognition.

Junctions within the center are another important area where accidents can take place; therefore, quit indicators and right-of-way signs are important. In pedestrian-heavy areas, indicators ought to signal both drivers and pedestrians to the visibility of forklifts, guaranteeing every person remains cautious.

Areas with high storage space shelfs and blind places pose one-of-a-kind difficulties. forklift safety signs. Signs in these zones ought to advise operators of limited presence and urge the use of spotters or added safety measures. By concentrating on these crucial places, organizations can develop a safer, much more effective functioning atmosphere for all

Height and Angle Considerations

When setting up forklift safety and security indicators, considering the elevation and angle of placement is vital to ensure maximum visibility and effectiveness. Proper height guarantees that operators and pedestrians can conveniently see the indicators without blockage. Usually, safety and security indicators must be installed at eye degree, which is around 4 to 6 feet from the ground. This placement allows individuals to quickly notice and review the indicators as they browse the area.

The angle of the indication is similarly vital. Indications need to be angled in the direction of the line of sight of coming close to website traffic or workers. If an indicator is suggested to caution forklift drivers, it must be positioned directly in their field of sight, ideally vertical to their direction of traveling. In locations with numerous seeing angles, think about using double-sided signs or angled braces to keep exposure from numerous directions.

In addition, making certain that the indications are not blocked by other items, equipment, or shelving systems is important. Clear sightlines help stop accidents and boost overall safety and security. By thoughtfully taking into consideration height and angle, you can considerably boost the effectiveness of forklift safety indications, therefore cultivating a much safer workplace.

Signs Product and Resilience

Choosing the proper product for forklift security indicators is critical for guaranteeing their long life and effectiveness. In environments where forklifts run, indicators are often exposed to extreme problems, consisting of physical impacts, chemical spills, and differing temperature levels. Picking resilient materials like aluminum, high-density polyethylene (HDPE), and polyvinyl chloride (PVC) can significantly improve the indicators' life-span.

Aluminum is a preferred selection because of its resistance to rust and corrosion, making it perfect for both indoor and outdoor setups. In addition, its light-weight nature assists in very easy company website setup and repositioning. HDPE is another robust alternative, understood for its outstanding resistance to chemicals and impact. It is particularly ideal for setups where chemical exposure is prevalent. PVC, on the various other hand, uses a good equilibrium between resilience and cost-effectiveness, making it a common selection for many commercial atmospheres.

Moreover, the printing method used on these products likewise contributes in toughness. UV-resistant inks and protective laminates aid in avoiding fading and damage from sunshine and other environmental factors. Complying with these factors to consider guarantees that forklift safety and security signs stay noticeable and clear over extensive periods, consequently maintaining a risk-free workplace.

Making Sure Indicator Visibility

While choosing sturdy materials for forklift security indicators is essential, guaranteeing their visibility is similarly vital for maintaining a risk-free atmosphere. Reliable visibility can be accomplished with calculated positioning, proper illumination, and utilizing high-contrast shades. Indicators should be positioned at eye level and in places where operators and pedestrians are most likely to see them, such as at access points, crossways, and locations with high traffic.

Correct illumination is important to guarantee that signs are visible in all conditions. Mounting appropriate illumination in dimly lit locations or using reflective materials on signs can considerably enhance presence.

In addition, preventing visual clutter around the signs is necessary. Way too many signs in one location can bewilder and confuse people, lowering the efficiency of each sign. Clear, succinct messaging and making sure indications are without obstructions such as tools More Info or storage space items will certainly even more enhance their presence and effectiveness, adding to a much safer workplace setting.

Regular Examination and Maintenance

Uniformity is crucial to maintaining the performance of forklift safety indicators, making routine examination and maintenance indispensable. To make sure these signs remain to communicate essential information plainly, they should be consistently looked for deterioration, fading, or obstruction. forklift safety signs. With time, direct exposure to the components and functional activities can deteriorate their visibility and legibility, weakening their objective

During assessments, analyze each sign's condition, ensuring index text and symbols stay clear and lively. Any kind of indications showing indications of damage or fading should be quickly replaced.

Conclusion

Appropriate positioning and visibility of forklift safety indicators are essential in reducing workplace accidents. Positioning signs at crucial locations such as entrance and exit points, center junctions, and high-traffic storage areas, while guaranteeing they are mounted at eye degree and tilted in the direction of oncoming traffic, enhances their effectiveness.

Report this page